- Home

- What We Offer

Medical Solution Suite

Corporate Gift

- About Us

- Market Application

- Partnership

- Contact Us

- News & Events

- 𝐌𝐞𝐝𝐢𝐜𝐚𝐥 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧 𝐒𝐮𝐢𝐭𝐞

- – Medical Extrusion Tubing

- – PTFE Product

- – Heat Shrink Tube

- – Mandrel

- – Consumables

- 𝐌𝐞𝐝𝐒𝐄𝐀 𝐑𝐞𝐭𝐚𝐢𝐥

- – Retail – Dacco (Mama & Baby Gift)

- – Retail – Dacco (Maternity Consumables)

- – Retail – Dacco (Maternity Aid)

- – Retail – Dacco (Maternity Pad)

- – Retail – Dacco (Mummies Fashion)

- – Retail – Dacco (Body Shaper)

- – Retail – Dacco (Baby Wipe)

- – Retail – Dacco (Baby Towel)

- 𝐌𝐞𝐝𝐒𝐄𝐀 𝐆𝐢𝐟𝐭

- – Personalized Gift

- – Signature MedTEA

- 𝐌𝐞𝐝𝐟𝐲-𝐑𝐢𝐧𝐠

- – Why Medfy-Ring

- – Features of Medfy-Ring

- – Product Specification

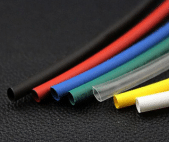

Medical Heat Shrink Tube

Categories

Contact Info

-

+65 82854986

(Singapore HQ) - sales@medseaforte.com

- 7 Temasek Boulevard, #12-07, Suntec Tower One, Singapore 038987

What is a Heat Shrink Tube

Heat shrink tubing is essential in medical applications, offering a high-performance solution for protecting sensitive components from harsh conditions. Acting as a tight, strong protective cover, it protects core components from extremes such as heat, shock, corrosion, moisture, chemical exposure, and more. Materials like FEP, PET, and PO are specifically chosen for their ability to withstand these environments while maintaining their structural integrity. At MedSEA Forte, we are committed to supplying top-tier medical heat shrink tubing, renowned for its quality and reliability. As one of the leading medical tubing suppliers in Singapore, our medical heat shrink tubing is engineered to shrink at precise temperatures, ensuring a consistent, reliable fit every time. This capability is critical in medical devices where non-reactivity and stability are paramount. By forming a tight barrier against external contaminants and mechanical stress, our range of heat shrink tubing significantly enhances the lifespan and functionality of medical devices, playing a critical role in modern medical treatments.

Enhancing Medical Device Performance with Heat Shrink Tubing

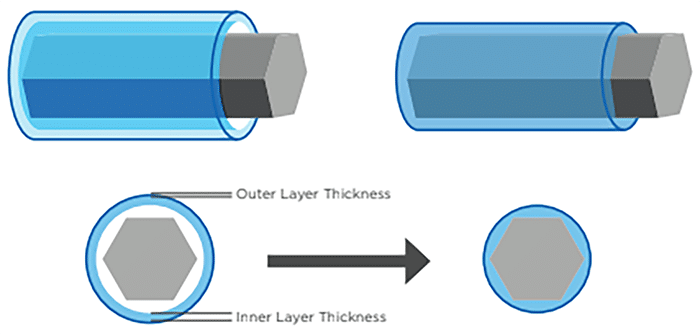

Heat shrink tubing is an essential component in medical manufacturing, notably in the production of catheters. This tubing is applied over various medical components and subjected to heat, causing it to shrink and tightly conform to the underlying shapes. This process not only firmly secures internal components but also fortifies the device with a smooth, resilient exterior capable of withstanding medical procedures’ demanding requirements.

In the visual sequence, from left to right, the transformation of heat shrink tubing is depicted: starting as a loose, flexible cover before heat application, then contracting snugly around a medical device component, culminating in a durable, protective layer.

A prime example of its crucial application is in catheter reinforcement and customization. Here, the tubing enhances the catheters’ structural integrity, offers a frictionless surface to ease patient discomfort, and permits modifications like radiopacity for enhanced imaging visibility and lubricity for easier insertion. This makes medical heat shrink tubing vital not only for its protective qualities but also for its role in improving the overall functionality and safety of catheters and other critical surgical instruments.

A Trusted Supplier of Medical Heat Shrink

MedSEA Forte is a leading provider of high-quality medical heat shrink tubing in the Southeast Asian region. We are committed to delivering innovative and reliable solutions that meet the stringent demands of the medical device industry. Our advanced manufacturing capabilities and extensive expertise allow us to provide a comprehensive range of medical-grade heat shrink tubing tailored to your specific needs. We prioritize precision engineering to ensure our tubing delivers exceptional performance, safety, and reliability in critical medical applications.

Our Range Of Medical Heat Shrink Tubes

FEP Heat Shrink Tube

FEP (fluorinated ethylene propylene) heat shrink tubing is engineered for high-precision medical applications, offering exceptional chemical resistance and durability under extreme conditions.

FEP heat shrink tubing is particularly useful in intricate medical processes such as aiding in the reflowing of catheter shafts, ensuring secure joint bonding, and facilitating the fusing of catheter shaft components.

MedSEA Forte offers FEP heat shrink tubing with ultra-thin walls and extremely high tensile strength, making it ideal for demanding medical applications. Our FEP tubing boasts a low shrinkage temperature, smooth inner and outer surfaces, excellent biocompatibility, a high radial shrinkage rate, and excellent dielectric strength.

We offer the following standard products, and custom dimensions and colors are available upon request:

- Standard Lengths: 1270mm (Standard 1 to 5)

- Shrink Ratio: 1.1:1 (except for Standard 4, which is <1.2:1)

- Colors: Black, green, white, and transparent

- Diameter: 0.38 – 7.00 mm (custom sizes >7.00mm available)

- Wall Thickness: 0.005 – 0.100mm (custom sizes >0.100mm available)

Key Characteristics

Shrink Ratio

1.3:1 | 1.6:1 | 2:1

Excellent Chemical Resistance

High

Transparency

Easy

Peel

Off

High

Dielectric

Strength

Biocompatibility

PET Heat Shrink Tube

PET heat shrink tubing is essential for various medical device applications, providing high strength and clarity and enhancing device safety and functionality.

Specifically, PET heat shrink tubing is integral in applications, including vascular interventions, structural heart procedures, tumor treatments, and various fields such as electrophysiology, gastroenterology, respiratory care, and urology. It is highly valued for its outstanding insulation capabilities, protective qualities, and ability to add structural stiffness to medical devices. Additionally, PET tubing is used for sealing, fixation, and providing strain relief in complex medical instruments, ensuring reliable performance and patient safety during critical procedures.

Key Characteristics

Superior

Dielectric

Strength

Enhances

Stiffness with

Minimal Profile

Increase

Robust Hoop

Strength for

Secure Braid

Termination

Thermal Stability

across a Wide

Temperature

Range

Ideal for Protective

Coatings and

Component

Bundling SH

Polyolefin (PO) Heat Shrink Tube

Polyolefin (PO) heat shrink tubing is renowned for its durable, cross-linked structure, offering excellent mechanical and physical properties suited for medical applications. This tubing is designed to provide reliable protection and strength, making it indispensable for medical devices that require consistent performance under various conditions.

The significant advantage of polyolefin tubing lies in its low shrink temperature of 90 degrees Celsius, which allows for easy application using basic tools such as a heat gun, a small butane torch, or a low-temperature radiant oven. This feature simplifies the manufacturing and maintenance processes, making it a practical choice for medical environments. Additionally, PO heat shrink tubing is celebrated for its remarkable longevity and stability, maintaining its integrity without deterioration at standard temperatures, and ensuring long-term reliability in medical settings.

Key Characteristics

Exceptional

Optical

Clarity

Enhanced

Durability and

Strength

Superior

Chemical

Resistance

Highly Flexible

for Varied

Applications

Economical without Compromising Quality

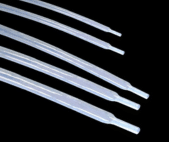

PTFE Heat Shrink Tube

PTFE medical heat shrink tubing, also known as polytetrafluoroethylene tubing, offers superior chemical resistance, biocompatibility, and low friction properties, making it ideal for high-purity applications like catheters and endoscopes. The outstanding lubricity of PTFE medical tubing significantly reduces friction, facilitating smooth and safe insertion into the human body. This feature is crucial in minimizing patient discomfort and risk during invasive procedures. Additionally, PTFE’s chemical inertness ensures that it does not react adversely with human tissue or other medical substances, making it a safe choice for long-term medical applications.

Key Characteristics

Chemical Inertness

High Thermal Stability

Smooth Surface Finish

Excellent Dielectric Properties

Biocompatibility

Medical Applications of Heat Shrink Tubing

Encapsulation

Insulation

Heat shrink tubing acts as an electrical insulator, which is particularly crucial in electrosurgical devices as it prevents accidental contact and ensures safe operation. This insulation property is vital for patient and practitioner safety.

Wire Harness

In medical devices with complex wiring systems, heat shrink tubing bundles and organizes wires, preventing tangling and damage. This streamlined organization improves device functionality and maintenance.

Catheter Protective Jacket

Why Choose MedSEA Forte's Medical Heat Shrink Tubing

MedSEA Forte provides high-quality medical heat shrink tubing solutions tailored to the unique needs of medical device manufacturers.

Superior Quality and Precision

We maintain strict quality control measures throughout our manufacturing process, ensuring that our medical heat shrink tubing meets the highest standards of precision and performance. Our tubing is manufactured with tight tolerances to ensure optimal functionality and compatibility with your medical devices.

Customer-Centric Approach

At MedSEA Forte, we prioritize customer satisfaction. Our team of experts works closely with you to understand your specific needs and provide tailored solutions that meet your unique requirements. We are committed to building long-term partnerships based on trust, reliability, and open communication.

Advanced Manufacturing Capabilities

Our state-of-the-art manufacturing facility is equipped with advanced technology and operated by a team of skilled professionals. This allows us to produce high-quality medical heat shrink tubing with exceptional consistency and efficiency, ensuring a reliable supply chain for your medical device production.

Related Products

Explore other essential components available in our comprehensive medical solution suite.

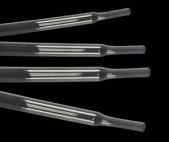

Mandrels

MedSEA Forte specializes in producing high-performance, medical-grade mandrels for parylene coating applications. Our advanced manufacturing techniques and expertise ensure precise and reliable solutions tailored to the specific needs of medical device applications.

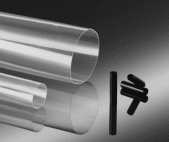

PTFE Products

MedSEA Forte possesses extensive expertise in PTFE (polytetrafluoroethylene) product manufacturing. We leverage our deep knowledge and technical skills to deliver a wide range of high-performance PTFE solutions, including medical-grade PTFE tubing, that are tailored to meet the unique demands of various applications.