- Home

- What We Offer

Medical Solution Suite

Corporate Gift

- About Us

- Market Application

- Partnership

- Contact Us

- News & Events

- 𝐌𝐞𝐝𝐢𝐜𝐚𝐥 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧 𝐒𝐮𝐢𝐭𝐞

- – Medical Extrusion Tubing

- – PTFE Product

- – Heat Shrink Tube

- – Mandrel

- – Consumables

- 𝐌𝐞𝐝𝐒𝐄𝐀 𝐑𝐞𝐭𝐚𝐢𝐥

- – Retail – Dacco (Mama & Baby Gift)

- – Retail – Dacco (Maternity Consumables)

- – Retail – Dacco (Maternity Aid)

- – Retail – Dacco (Maternity Pad)

- – Retail – Dacco (Mummies Fashion)

- – Retail – Dacco (Body Shaper)

- – Retail – Dacco (Baby Wipe)

- – Retail – Dacco (Baby Towel)

- 𝐌𝐞𝐝𝐒𝐄𝐀 𝐆𝐢𝐟𝐭

- – Personalized Gift

- – Signature MedTEA

- 𝐌𝐞𝐝𝐟𝐲-𝐑𝐢𝐧𝐠

- – Why Medfy-Ring

- – Features of Medfy-Ring

- – Product Specification

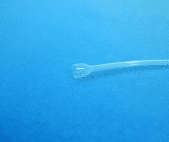

PTFE Medical Tubing

Categories

Contact Info

-

+65 82854986

(Singapore HQ) - sales@medseaforte.com

- 7 Temasek Boulevard, #12-07, Suntec Tower One, Singapore 038987

Overview of Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene (PTFE), discovered in 1938, has become integral to medical device applications due to its unique properties. This synthetic fluoropolymer, derived primarily from fluorite, is noted for its exceptional non-stick qualities, chemical inertness, and high thermal stability. In medical applications, PTFE tubing is pivotal for its low coefficient of friction and extremely broad working temperature range, making it suitable for critical roles such as protective linings in catheters for delivery channels for medical devices and insulative sheaths in medical electronics.

PTFE medical tubing, with its origins rooted in intricate chemical transformations, begins as a fluorine gas that reacts with hydrocarbon gases to create PTFE resin. This resin, processed through stages like compression molding and precise extrusion, results in tubing that meets the exacting standards required in medical technologies. Some types of PTFE tubing in medical applications include multi-lumen tubes for complex device pathways, medical heat shrink tubing for encapsulating other components, and ultra-thin-wall tubes for minimally invasive procedures. The key benefits of these in medical devices include their high dielectric strength, resistance to temperature extremes, and biocompatibility, which ensure they perform reliably under rigorous medical use. With its unparalleled chemical resistance, PTFE has become an ideal polymer for the chemical and analytical sciences.

PTFE in Medical Devices

PTFE’s exceptional properties make it a preferred material for a wide range of medical devices. Its biocompatibility ensures it can be used safely within the human body without causing adverse reactions. The chemical inertness of PTFE means it won’t react with bodily fluids or medications, ensuring the integrity of the device and patient safety. Furthermore, PTFE’s resistance to high temperatures allows it to withstand sterilization processes, maintaining its properties and ensuring device sterility.

Given these properties, the production of PTFE medical tubing involves a carefully controlled extrusion process to achieve the precise dimensions and quality required for medical applications. While the intricacies of this process are complex, the general steps are as follows:

- Preparation: The extrusion equipment is set up and calibrated.

- Heating and Forming: PTFE resin is heated and shaped.

- Extrusion: The heated resin is forced through a die to create the tubing.

- Cooling and Sintering: The tubing is cooled and then heated to strengthen its structure.

- Final Processing: The tubing is cut, polished, and inspected to meet quality standards.

MedSEA Forte is a leading provider of medical-grade PTFE tubes in the Southeast Asian region. We specialize in custom extrusion, working closely with clients to produce PTFE tubing with precise specifications tailored to their unique medical device applications.

For a more detailed explanation of the extrusion process, please visit our Medical Extrusion Tubing page.

PTFE Medical Tubing Types

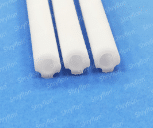

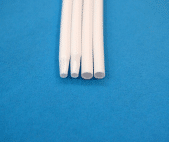

PTFE Single Lumen Tube

PTFE Multi Lumen Tube

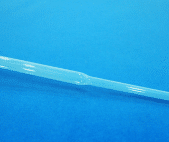

PTFE Heat Shrink Tube

PTFE Ultra Thin Wall Tube

PTFE Special Section Mandrel

PTFE Color Marking Tube

PTFE Liner

PTFE Sheath

Key Features of Our Medical PTFE Tubes

Ultra Thin Wall

High Dielectric Strength

Torque Transmission

Excellent Temperature Withstanability

(Up To 260 °c / 500 °f)

Usp Class Vi Bio Biocompatibility

Sterilizable (Eto)

Excellent Coefficient Of Friction

Excellent Chemical Resistance

High Column Strength

Applications of PTFE in Medical Devices

Balloon Catheters

Delivery System

Introducer Sheaths

Wire and Cable Insulation

Analytical and Fluid Management Tubing

Material Properties of PTFE Medical Tubing

PHYSICAL | ASTM | PTFE |

|---|---|---|

Density (g/cm3) | D792 | 2.16 – 2.18 |

Water Absorption (%) | D570 | < 0.01 |

Oxygen Index (%) | D2863 | > 95 |

MECHANICAL | ASTM | PTFE |

|---|---|---|

Hardness, Shore D | D2240 | 50 – 65 |

Ultimate Tensile Strength (MPa) | D638 | 21 – 35 |

Elongation at Break (%) | D638 | 300 – 500

|

Modulus of Elasticity (MPa) | D638 | 392 |

Flexural Modulus (MPa) | D790 | 490 – 588 |

Coefficient of Friction | D1894 | 0.02 – 0.10 |

ELECTRICAL | ASTM | PTFE |

|---|---|---|

Volume Resistivity (Ω – cm) | D257 | < 1.0 × 10¹⁸ |

Dielectric Constant 1 MHz | D150 | 2.10 |

Dielectric Strength (V/mil) | D149 | 457 – 483 |

THERMAL | ASTM | PTFE |

|---|---|---|

Thermal Conductivity (W/m – K) | D433 | 0.025 – 0.3 |

Maximum Service Temp, Air (°C) | na | 260 |

Melt Temp (°C) | D4591 | 326 – 327 |

Decomposition Temp (°C) | AIR | 505 |

Coefficient of Thermal Expansion, Linear 20° (μm/m-°C)

| D696 | 100 |

Why Choose MedSEA Forte's PTFE Medical Tubing

MedSEA Forte is dedicated to providing high-quality PTFE medical tubing solutions that meet the stringent requirements of the medical device industry.

Superior Quality and Precision

We maintain strict quality control measures throughout our manufacturing process, ensuring that our PTFE medical tubing meets the highest standards of precision and performance. Our tubing is manufactured with tight tolerances to ensure optimal functionality and compatibility with your medical devices.

Customer-Centric Approach

At MedSEA Forte, we prioritize customer satisfaction. Our team of experts works closely with you to understand your specific needs and provide tailored solutions that meet your unique requirements. We are committed to building long-term partnerships based on trust, reliability, and open communication.

Advanced Manufacturing Capabilities

Our state-of-the-art manufacturing facility is equipped with advanced technology and operated by a team of skilled professionals. This allows us to produce high-quality PTFE medical tubing with exceptional consistency and efficiency, ensuring a reliable supply chain for your medical device production.

Related Products

Explore other essential components available in our comprehensive medical solution suite.

Mandrels

MedSEA Forte specializes in producing high-performance, medical-grade mandrels for parylene coating applications. Our advanced manufacturing techniques and expertise ensure precise and reliable solutions tailored to the specific needs of medical device applications.

Heat Shrink Tubes

We offer a range of specialized heat shrink tubing solutions designed for critical medical applications. Our high-quality, precision-engineered tubing ensures reliability, safety, and optimal performance in medical devices and equipment.